S&OP is a business process that links the corporate strategic plan to daily operations plans and enables companies to balance demand and supply for their products.

(Gregory, 1999; Dwyer, 2000; Wight, 1999)

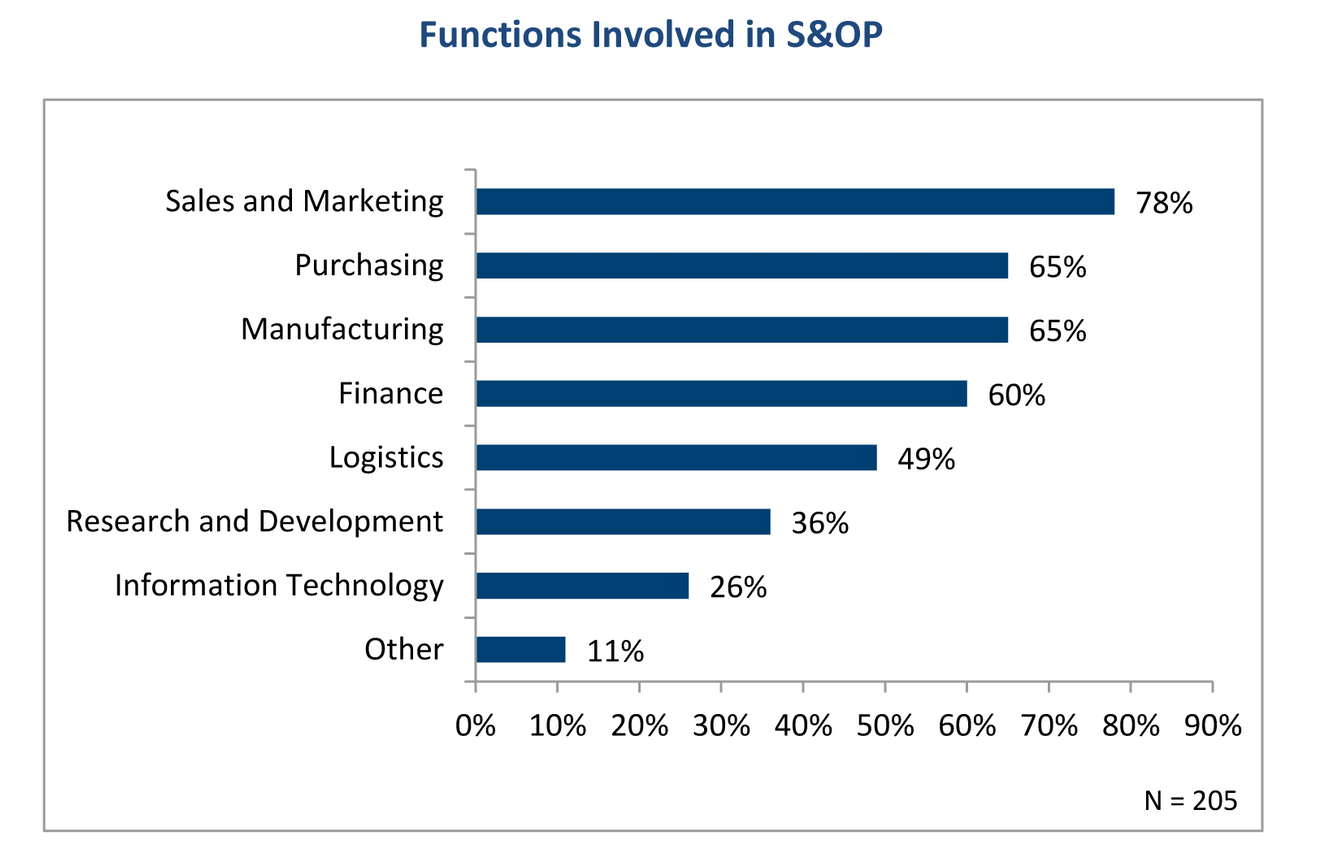

Sales and Operations Planning, or simply S&OP, is a cross-functional planning process to align sales, customer service, manufacturing, marketing, finance, and supply chain (including logistics and procurement). It helps business management make informed decisions while considering all known factors that could impact future demand, including new product introductions and promotions.

The S&OP process in itself is the larger plan in which demand and supply planning play an integral part. Many companies that implement demand planning and supply planning believe they have an S&OP process in place. However, they often fail to fully utilize the collaborative benefits of manufacturing and inventory planning with demand and supply planning for organization-wide growth.

In this article, we will talk about various aspects of S&OP. We will also look at the indulgence of technology to make it better.

S&OP Best Practices

While there is no singular handbook for Sales and Operations Planning, organizations that follow certain best practices can reap the maximum benefits out of it.

- Fixed Regular Meetings: S&OP meetings need to be regular to achieve tangible results.

- Discussions must be data-driven and not opinion-based: Since opinions will be varied, considering the verticals involved, all conversations and forecasts need to be data-driven. Data-driven discussions are objective and quantifiable and lead to greater transparency and accountability.

- Participation of all departments: Participation along with active representation and feedback is vital for fruitful meetings. The exclusion of any department from the S&OP meeting will make the entire process redundant.

- Collaborative but disciplined process, controlled at the helm: S&OP process is best guided by senior management so that it is strictly implemented.

- Using software & technology to integrate data and resources across departments.

The Stages of Sales and Operations Planning

1. Data Collection and Analysis

The first phase of the S&OP process begins with collecting and corroborating available data about product development, new product introductions, past sales, trends, and report forecasts.

Discussions must center on the introduction of new products, discontinuation of existing ones, etc. Although key inputs primarily come from sales and marketing; inputs from operations, supply, logistics, and finance should also be considered to review supply policies, inventory requirements, lead times, etc.

2. Demand Review

The second phase entails planning of demand considering external and internal factors that affect it.

Demand Planning helps forecast demand accurately and use it to optimize inventories and manage supply. It helps in gaining a competitive edge by understanding and predicting customer needs. Demand planning is a combination of sales, marketing, and product plans. You can draw a successful demand plan by understanding the sources of demand and including in its purview promotion plans, one-time events, new products, and launches.

The demand plan is measured either in units or revenue.

3. Supply Review

This stage answers the most pertinent question of what it takes to meet the demand plan most profitably. To answer this question, you will have to review the inventory and identify ways to optimize it. Demand Plan has to work in unison with a supply plan to make a measurable impact on operating costs.

A supply plan should consider demand variations that could arise out of various exigencies. It will help determine constraints in manufacturing and supply and helps in mitigating these. A well-drawn supply plan after various simulations will allow the distribution of inventory between manufacturing and sales in the most cost-effective way.

4. Pre-S&OP

This is the stage of financial review where all plans are one step away from the action. Actual costs are compared with budgets and forecasts to analyze forecast accuracy.

This stage of the S&OP process helps identify gaps and develop strategies to handle them by making adjustments to the demand and supply plans. It also involves adjusting key metrics to suit the organization’s needs. Also, all departments must adopt a shared metric perspective to gain a broader view and arrive at a trade-off that best achieves the organization’s objective.

5. Executive S&OP

The final phase of S&OP brings all plans into action. The S&OP Meeting is led by the company’s senior executive. It is where all plans are finalized, and a road map is devised for timely reviews.

The Benefits of S&OP

The Objectives of Sales and Operation Planning translates into benefits if the S&OP process is well executed. It leads to increased transparency between departments leading them to work in tandem. Increased communication between departments reduces blame-shifting and increases accountability. Accurately drawn demand and supply plans lead to better Inventory Management. With S&OP, the whole company works towards a common goal and track common numbers.

No process in a business can succeed if it doesn’t improve customer experience. For instance, Tata Steel, with the help of an S&OP platform, worked on pricing, procurement, and delivery forecasts. It helped them in connecting their downstream businesses seamlessly while offering more value to the consumer. The S&OP process improves inventory and the sales and marketing process. This, in turn, helps in delivering greater value to customers at optimal cost to the business. Any information about new product launches obtained by sales can be communicated to manufacturing on time to tweak production. For instance, customer feedback for a detergent company might indicate greater preference to refill packs of liquid detergents over bottled ones. This feedback, if utilized cross-functionally, will shape demand planning. It will also play a key role in manufacturing decisions with implications throughout the supply chain, from storage to transportation.

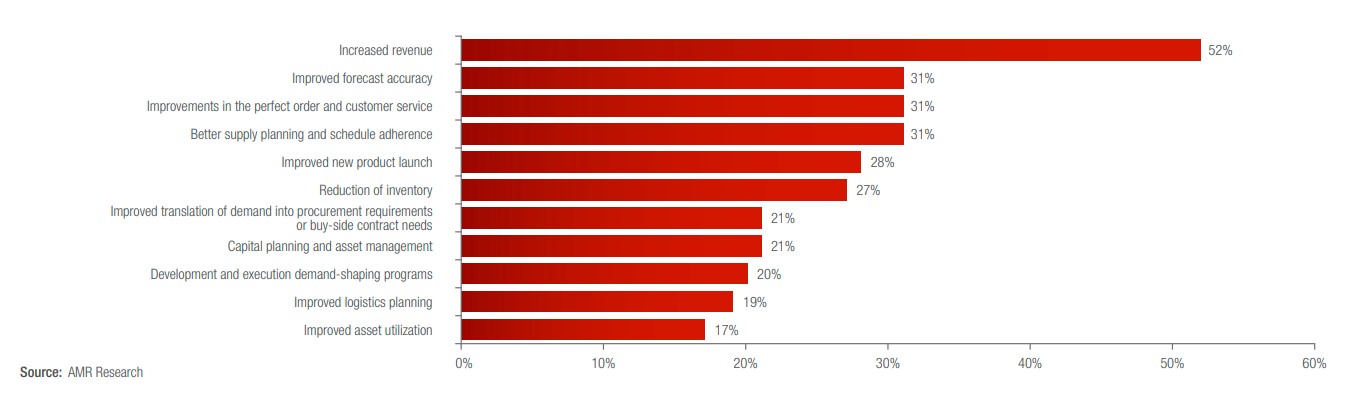

According to AMR research, more than 50 percent of companies that implement S&OP/IBP experience increased sales revenue.

The following graph illustrates this:

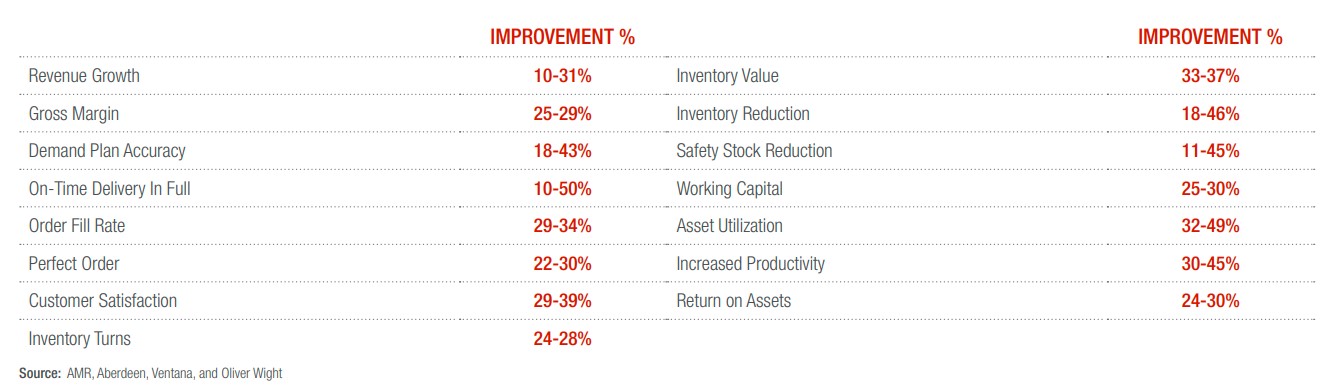

The following is the range of improvements cited by companies.

How to measure a company’s S&OP

To effectively evaluate a company’s S&OP, it is imperative to measure results in terms of inventory optimization, demand forecasts vs. actuals, and customer feedback. And to understand the impact created in these areas, businesses must identify KPIs and track them regularly.

While identifying KPIs, each business is different, with different requirements and objectives. Hence, it is difficult to zero down on a few specific KPIs for a particular company. Also, sales and operations planning is a continual process. Therefore KPIs tend to be dynamic and keep changing over meetings. The metrics for most businesses will be spread across but not limited to:

- Financial Metrics: Cash Flow, Overall profitability

- Manufacturing: Capacity utilization, Overhead costs, Machine Efficiency

- Customer Satisfaction: On-time delivery, Warranties & Returns, Servicing

- Forecast Accuracy: Demand & Supply forecast accuracy, Revenue & Spend projections.

- Inventory: Finished goods inventory, raw material inventory, Cycle time.

- Supply: Order fulfillment, Logistics, On-time delivery to the supplier, Carrier compliances.

Technology and S&OP

A major challenge while conducting S&OP is the copious amount of data brought to the table by all departments. These spreadsheets vary across indexes and can be time-consuming. This is where software packages for demand planning and supply planning come in handy.

S&OP software can run advanced analytics, run simulations, and create accurate forecasts that enable companies to meet financial goals. Software that provides external information related to vendor data and point of sale information, enables companies to forecast better. It helps companies prepare for different scenarios, ranging from a pandemic to customer preferences.

To give you an example, a well-executed S&OP process has revolutionized Del Monte’s business flows. The North American food production and distribution company, Del Monte, suffered from excess inventory and forecast issues before implementing S&OP. They worked around averages, and due to inaccurate forecasts, sales suffered. By integrating their supply and finance processes, they were no longer working with averages. Del Monte’s forecasts improved, and they managed to shorten their supply chain from two weeks to two days. This remarkable change led to increased profitability and helped in establishing a transparent process across the organization.

The world of business is full of examples of organizations that have successfully implemented S&OP and reaped benefits out of it. However, S&OP planning should be implemented with a far-sighted goal. It should be a continuous process that finds its place in the strategic decision-making of the company. S&OP is not a destination but a journey that companies embark on and need to commit to.