- Home

- Learn

- Manufacturing

- Using CRM to Improve Manufacturing Operations and Dealer Engagement

MANUFACTURING

Using CRM to Improve Manufacturing Operations and Dealer Engagement

Contents

Manufacturing has changed from craft production to mass production and now to smart manufacturing. Today’s manufacturers face a complex, competitive, and customer-led world.

Agility, responsiveness, and customer-centricity are now table stakes. Manufacturers must produce high-quality products at scale and personalize them. This presents challenges that traditional systems can’t solve.

Industry 4.0, with digital integration, data-driven decision-making, and smart automation, is accelerating this change. So, manufacturers are recognising the need for advanced tools like Customer Relationship Management (CRM) systems to manage onboarding and dealer relationships across the manufacturing value chain.

Running a manufacturing business without a robust CRM system in today’s digital age is like navigating a ship without a compass in stormy seas. Without a centralized dealer engagement system, you’ll face many challenges that will impact your efficiency, profitability, and competitiveness.

Let’s dive deeper into some of the challenges faced by manufacturers who haven’t yet adopted CRM:

In a non-CRM environment, dealer information is scattered across different departments and platforms. Sales teams might have their own spreadsheets; customer service might use a separate ticketing system, and production planning might use another database. This fragmentation leads to:

Without a centralized CRM, manufacturers struggle to:

Manual order processing is time consuming and error prone. This can lead to:

Without a unified customer view, it’s hard to provide timely and effective post sale support:

Without proper feedback mechanisms manufacturers miss out on valuable insights to drive product improvements:

According to the recent survey, manufacturing firms have seen CRM adoption increase by close to 86%, this highlights the role it has in streamlining sales processes and retaining dealers in a competitive market. Firms that holdout on digital transformation have a risk of falling behind their competitors who are using CRM to drive sales and increase retention.

Without a CRM system, you’ll miss out on growth and innovation opportunities. Without a full view of dealer interactions and preferences, you’ll struggle to see emerging market trends, new product opportunities, or service expansion areas.

As manufacturing moves towards more customized, on-demand production models, the need for robust customer relationship management becomes even more important. Manufacturers who don’t adopt CRM will fall behind competitors who can offer more personalised, responsive and efficient services to their dealers.

CRM systems have moved way beyond their original role as sales tools. In manufacturing, CRM is the central nervous system of the entire operation, connecting all departments and processes to create a customer-centric organization.

Here’s why CRM is key for modern manufacturers:

CRM gives you a full view of each dealer:

This gives you the ability to:

LeadSquared CRM gives you a 360-degree view of all dealer information, purchase history, and preferences, helping you tailor your approach much better.

By integrating with other systems like ERP and production planning CRM helps create a seamless flow of information across the organisation:

With a better view of the sales pipeline and historical data you can:

CRM can track customer feedback and product performance so you can:

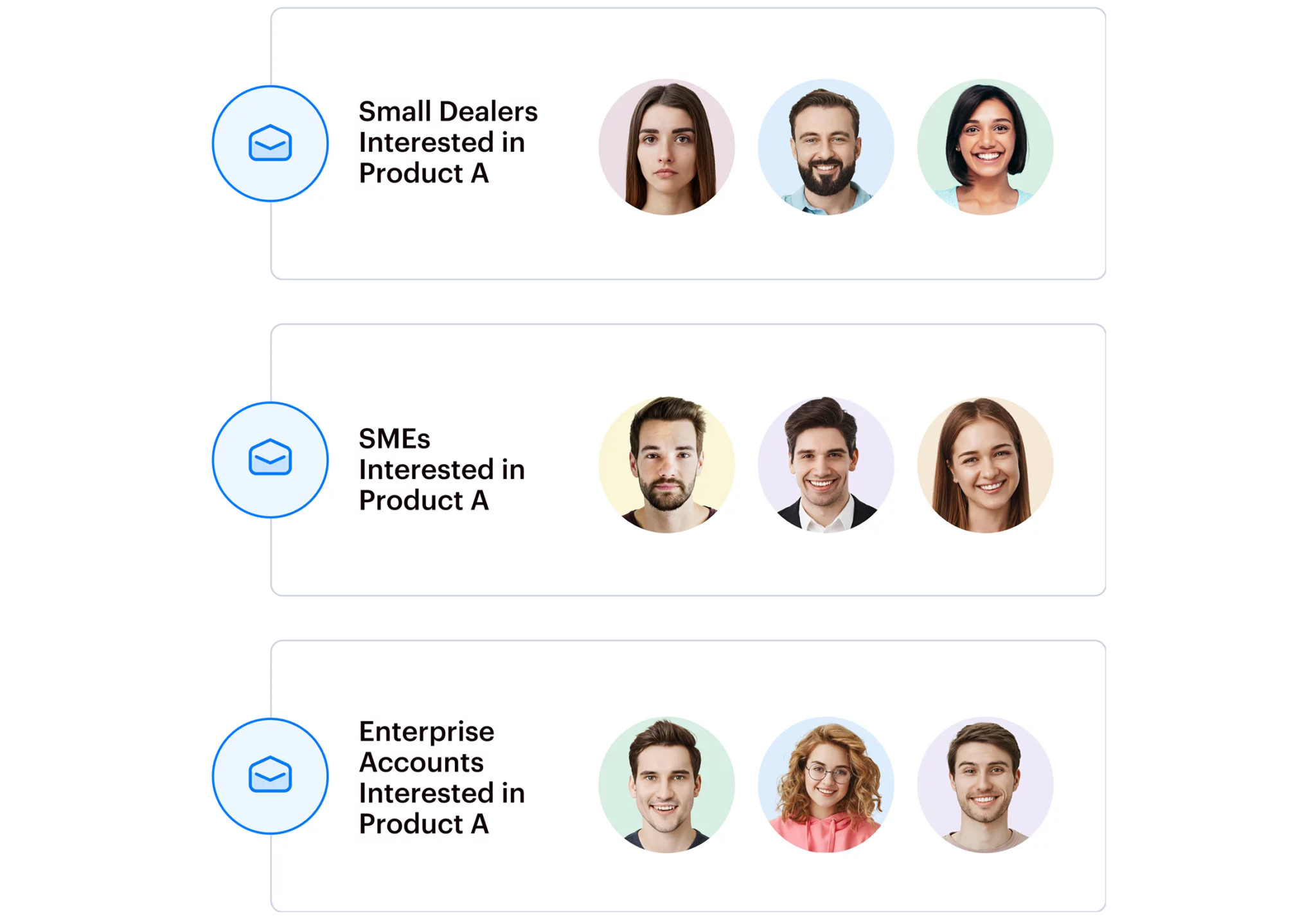

In an era of customisation CRM allows you to:

LeadSquared CRM allows you to automate personalized communications to all leads and customers. Personalized communication helps foster better customer relationships, improving potential of cross and upselling products.

According to a Grand View Research report the global CRM market is projected to hit USD 163 billion by 2030 and is expected to grow at a compound annual growth rate (CAGR) of 14.6% from 2025 onwards. This growth is partly driven by the increasing adoption of CRM in traditionally tech-shy sectors like manufacturing.

As manufacturers navigate the challenges of digital transformation, CRM systems like LeadSquared are becoming the must-have tools to stay competitive, efficient, and customer-focused in a complex market.

When choosing a CRM for manufacturing certain features stand out as most important. Here are the top 5 features to look for and how LeadSquared CRM addresses them:

LeadSquared provides a comprehensive mobile app allowing efficient field sales operations and improves overall productivity.

These features can lead to big operational efficiency gains. For example, a Nucleus Research study found that using mobile CRM saw a 26.4% increase in sales team productivity.

The benefits of CRM in manufacturing are real and measurable. A Nucleus Research study found CRM pays back $8.71 for every dollar spent. It’s even higher in manufacturing due to the complexity of manufacturing sales and customer relationships.

As manufacturers face increasing customer expectations, global competition, and the need for efficiency, CRM systems like LeadSquared are a must-have to stay competitive and grow in the Industry 4.0 era.

Choosing the right CRM is key for manufacturers. Here are the key factors to consider, with a focus on how LeadSquared addresses these:

LeadSquared Approach: LeadSquared has robust API and pre-built integrations with popular ERP systems so data flows seamlessly across your entire tech stack.

LeadSquared Approach: As a cloud-based solution, LeadSquared can scale to growing businesses from small manufacturers to large enterprises.

LeadSquared Approach: LeadSquared is designed with user experience in mind, has an intuitive interface that requires minimal training. Has a mobile app so sales and service teams can access and update information on the go, improving responsiveness and productivity.

LeadSquared Approach: LeadSquared has extensive workflow customization capabilities so manufacturers can customize the system to their needs. Its also a low-code platform so you can make changes without involving IT.

LeadSquared Approach: LeadSquared provides comprehensive support and training resources, including documentation, webinars, and a dedicated customer success team to ensure smooth implementation and ongoing optimization.

LeadSquared Approach: Pricing may vary based on your needs but LeadSquared has competitive pricing models and has shown strong ROI for its manufacturing customers as seen in case studies and success stories.

According to a Capgemini report 66% of industrial companies consider CRM as a high priority for their digital transformation initiatives. LeadSquared is positioning itself to meet this demand with industry specific features and integrations.

When evaluating LeadSquared or any other CRM for your manufacturing business, consider a demo or pilot program. This hands-on experience will help you see how the system fits your specific needs and processes. Pay attention to how the CRM handles your workflows, integrates with your existing systems and supports your team’s daily activities.

As we’ve seen above, CRM is no longer a nice to have for manufacturers. From streamlining operations and customer satisfaction to data driven decision making, the benefits of CRM in manufacturing are massive.

Operating without a CRM – fragmented data, inefficient processes and missed opportunities – is becoming impossible in today’s competitive world. By adopting CRM manufacturers can turn these challenges into opportunities for growth, efficiency and innovation.

Don’t just implement a CRM, leverage it as a tool to take your manufacturing business digital. Whether you choose LeadSquared or another solution, make sure it fits your processes and growth goals.

Ready to CRM your manufacturing business? The future of manufacturing is customer centric and efficient. Start now with LeadSquared CRM.